Block Making Machine - TC-QTJ4-40

Block Making Machine - TC-QTJ4-40

Product Description

Product Attributes

Model No.: TC-QTJ4-40

Applicable Industry: Other, Building Material Shops, Manufacturing Plant, Construction Works

Out-of-warranty Service: Video Technical Support, Online Support, Field Maintenance And Repair Service

Status: New

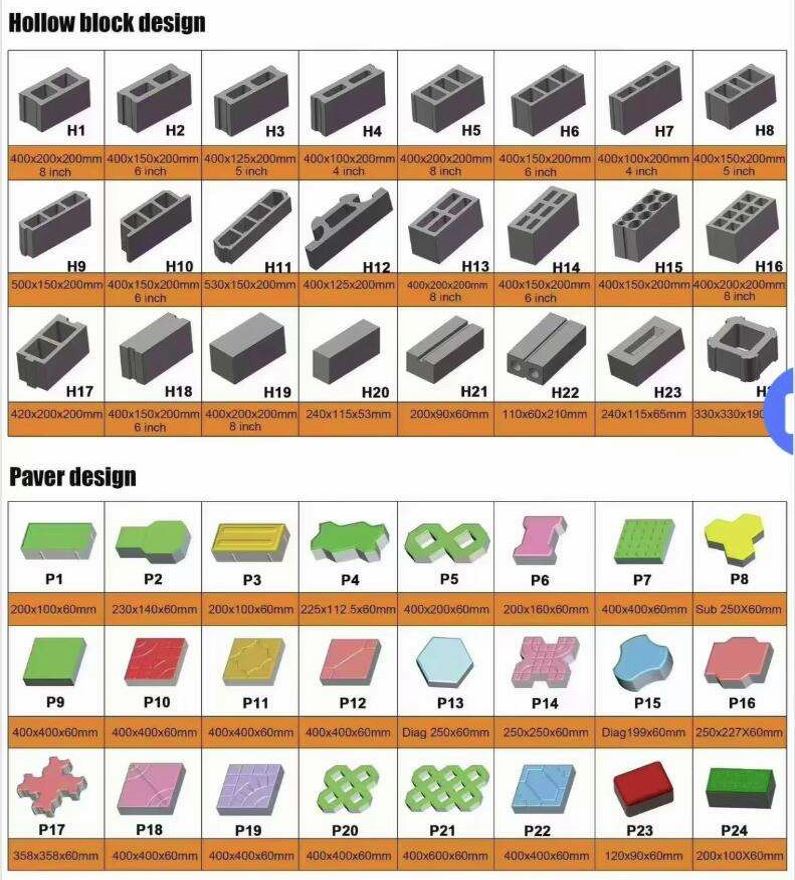

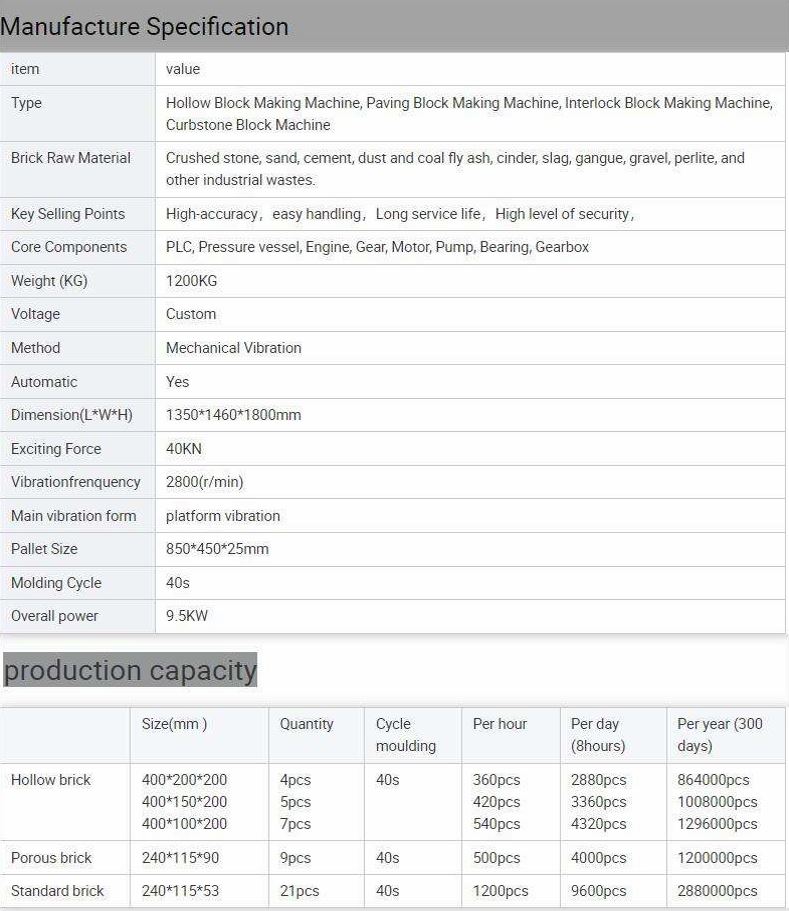

Species: Hollow Block Making Machine, Autoclaved Aerated Concrete Block (Aac), Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other

Brick Material: Cement

Processing: Brick Production Line

Way Of Working: Hydraulic Pressure

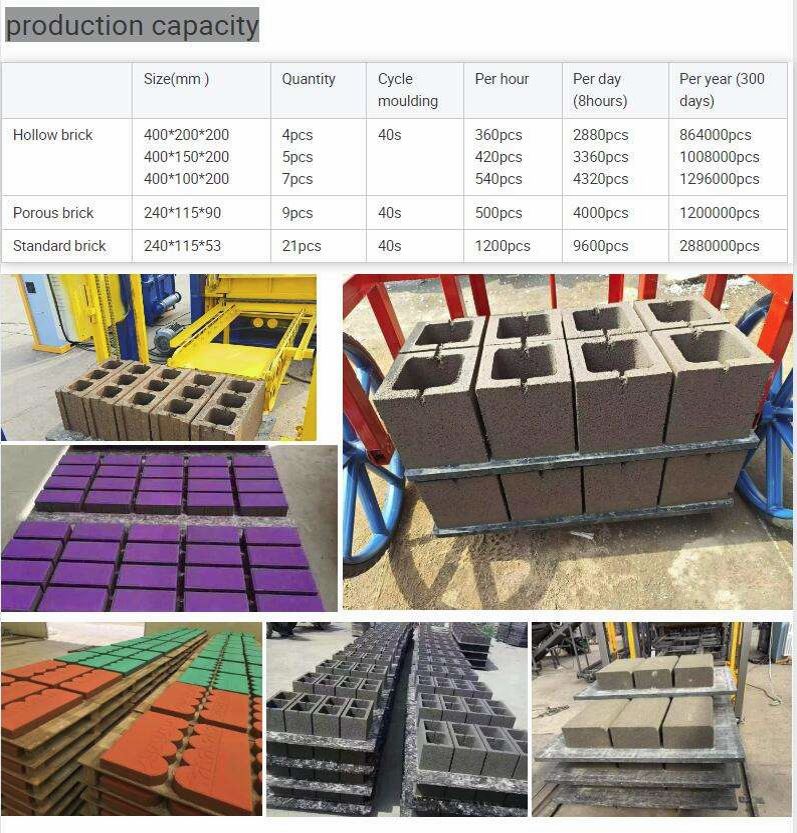

Production Capacity: 4480 Pcs/8hours, 5760 Pcs/8hours, 3400 Pcs/8hours

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Brick Size: 400*100*200 Mm, 400*120*200 Mm, 200*100*60 Mm, 300*150*100 Mm, 400*150*200 Mm, 240*115*90 Mm, 200*200*60 Mm, 230*220*115 Mm, 400*200*200 Mm, Other, 150*150*100 Mm

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Core Components: Motor, Other, Bearing, Pump, Engine, Gear

Automatic: No

Block Making Machine - TC-QTJ4-40 Fotoğraf Galerisi

Quick overview: TC-QTJ4-40 Block Making Machine

- What it is: A hydraulic block/brick making machine typically used to produce concrete blocks, bricks, or pavers. Models in this range often feature:

- Hydraulic press for compaction

- Interchangeable molds for different block sizes

- Optional vibration or compaction table

- PLC control or semi-automatic operation

- Common specs you might see (varies by manufacturer):

- Block sizes: e.g., 390×190×190 mm or similar

- Cycle features: one mold press per cycle with adjustable pressure

Power: 3-phase electrical supply, hydraulic motor

Output: depends on cycle time and mold—commonly several blocks per cycle

- What to verify with a supplier:

- Exact mold sizes and availability of alternate molds

- Hydraulic system pressure and oil type

- Electrical requirements and safety features

- After-sales support, spare parts, and maintenance

- Test run or demo data sheets (TDS)